Vermiculite

Vermiculite is extracted from open pits by drilling and blasting, then crushed and air separated from the host rock. For a consistent and dependable product, the ore is extracted from a variety of locations inside the mine and mixed together. 2 Tetrahedral Sheets for every 1 Octahedral Sheet Vermiculite is 2:1 clay. It is a clay with a restricted expansion and a modest shrink-swell capability. There is a cautious exchange capacity of 100-150 meq/100g in vermiculite. We are the top vermiculite supplier.

Vermiculite clays are micas where the potassium ions between the molecular sheets have been replaced by mg and iron ions. Vermiculite is non-combustible and insoluble in water or organic solvents, making it ideal for a wide range of applications. Because of its intrinsic stability, exfoliated vermiculite’s bulk density size and aspect ratio may be adjusted to suit certain end purposes. Vermiculite is increasingly being employed in situations where safety and health are of the utmost concern.

Types Of Vermiculite:

CRUDE VERMICULITE

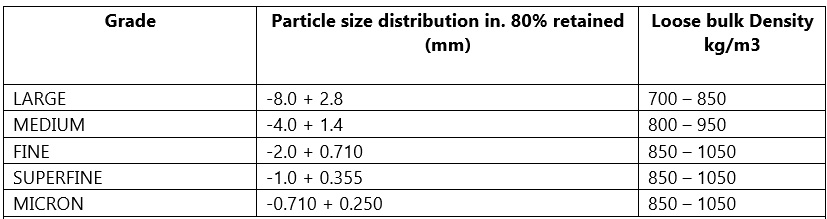

Crude vermiculite from the mine consists of golden / brown / silver, flakes which are carefully classified into five grades – each having a specified range of particle sizes. The coarsest grade comprises particles ranging between 1mm and 7mm, while the finest grade consists of particles between 0.710mm and 0.250mm in size. The loose bulk density of crude Vermiculite varies with the grade, but is typically between 700 and 1050 kg/m3.

EXFOLIATED VERMICULITE

The exfoliation process is carried out commercially by passing crude vermiculite through a furnace chamber in a controlled manner. The crude vermiculite then expands at right angles to the cleavage planes, producing concertina-shaped particles many times their original volume.

Why does vermiculite exfoliate?

The interlayer water is an essential component in the vermiculite. When a particle of vermiculite is rapidly heated, the interlayer crystalline water transforms into steam. The pressure of this steam evolution, forces the silicate layers apart from one another and the vermiculite flake forms an elongate concertina like particle twenty to thirty times its original thickness.

Grades:

Crude Vermiculite from the mine consists of golden to brown flakes which are carefully classified into five grades – each with a specified range of particle sizes, as detailed in the table below:

* The above specified values may vary to the actual values

Exfoliated Vermiculite:

Vermiculite is most widely used in its exfoliated form. The concertina-shaped granules of exfoliated vermiculite are non-combustible as well as being insoluble in water and all organic solvents. Safe and easy to handle, exfoliated vermiculite is available in the market place in five different grades as shown in the table below:

Volume Yields for Exfotliated Vermiculite:

* The above specified values may vary to the actual values

Applications of Raw Vermiculite

Fire protection

It is a good fire proofing material for fire proof plates because of its thermal stability and lack of toxicity at high temperatures.

Friction Lining

Vermiculite is currently widely utilised as a safe replacement to asbestos in the friction lining business and plays a significant role in this sector.

Horticulture

It has been used in agriculture because its porous nature greatly enhances soil aeration and avoids rotting plants.

Buildings and constructions

Expanded vermiculite is a good heat and sound insulator due to its porous structure, making it an important use as bulk insulation for floors and roofings. It is also simple to use, efficient, long-lasting, environmentally friendly, and fire-safe.

Packing Material

It is appropriate for use in air freight since it is inorganic and does not pose any possible fire concerns. It is used to pack fruit, bulbs, and tubers and also acts as an excellent barrier against shocks and inappropriate handling.

Textured ceilings

Vermiculite is a decorative or textured ceiling finish that is sometimes referred to as a popcorn ceiling. Renovations and changes frequently expose sections that have not been treated with vermiculite and must be included into the current plan.

Bitumen coated vermiculite screeds

As a dry, lightweight roof screed, vermiculite covered with a bituminous binder can be utilised. This form of screed has minimal heat conductivity, a low moisture content, and is simple to install.

Energy conservations

It is a high-quality and reasonably priced heat insulator constructed from expanded vermiculite insulation panels. Bulk expanded vermiculite is used to fill holes in walls and other structures, as well as ceilings and insulation.

Vermiculite Plasters

Gypsum or Portland cement can be used to make vermiculite plasters. They have benefits such as increased workability, lower thermal conductivity, excellent fire resistance, and improved adhesion.